How to post-process co-polyesters

Of course we love our prints as they are. We put great effort to choose the best materials and the finest materials. With our “How To…” posts we want everybody to be able to create the best prints possible on a wide variety of printers. We have written before about post-processing our metal filled filaments, which literally truly shine when processed the right way. More links to blogs about post-processing these special filaments can be found here.

Beyond the special filaments, which have great aesthetic properties, we also have our range of co-polyesters: nGen, colorFabb_XT and colorFabb_HT and we received quite a few questions about post-processing these materials. To find out more about the materials themselves, check out the blog we have written before by clicking here.

Developed by Eastman Chemical Company, Eastman Amphora™ 3D polymers are the basis of our co-polyesters and offer a low-odor, styrene-free choice that is uniquely suited for 3D printing applications. With Amphora, items can be created that are more functional, more durable, more efficient, and attractive. With superior melt strength and dimensional stability, our range of co-polyesters deliver advanced bridging capabilities to create stronger and more detailed items—with low odor and low emissions.

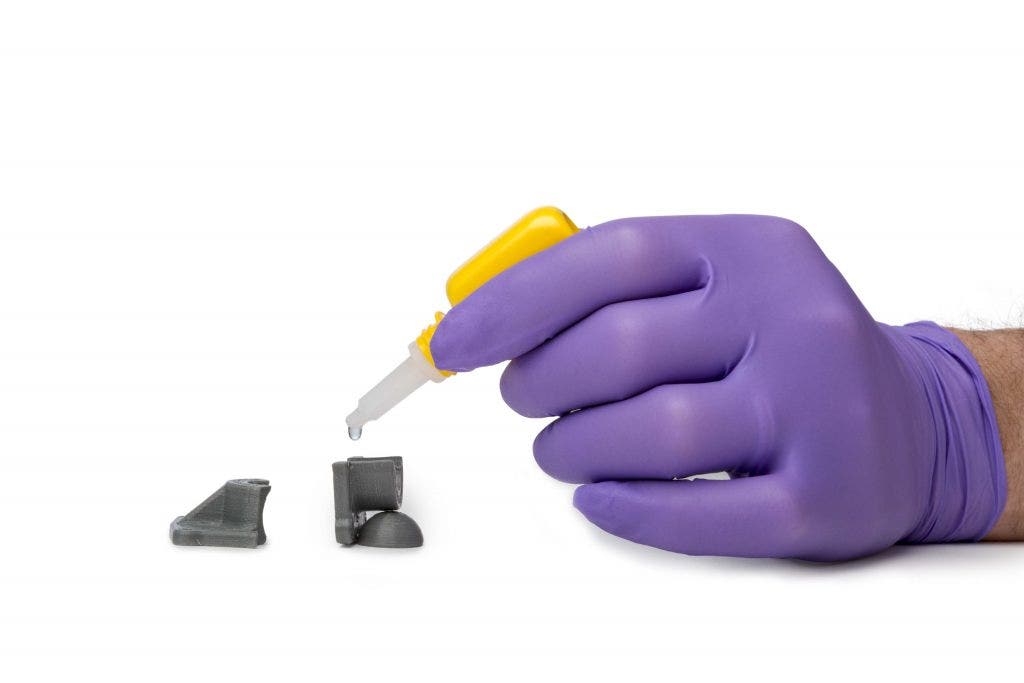

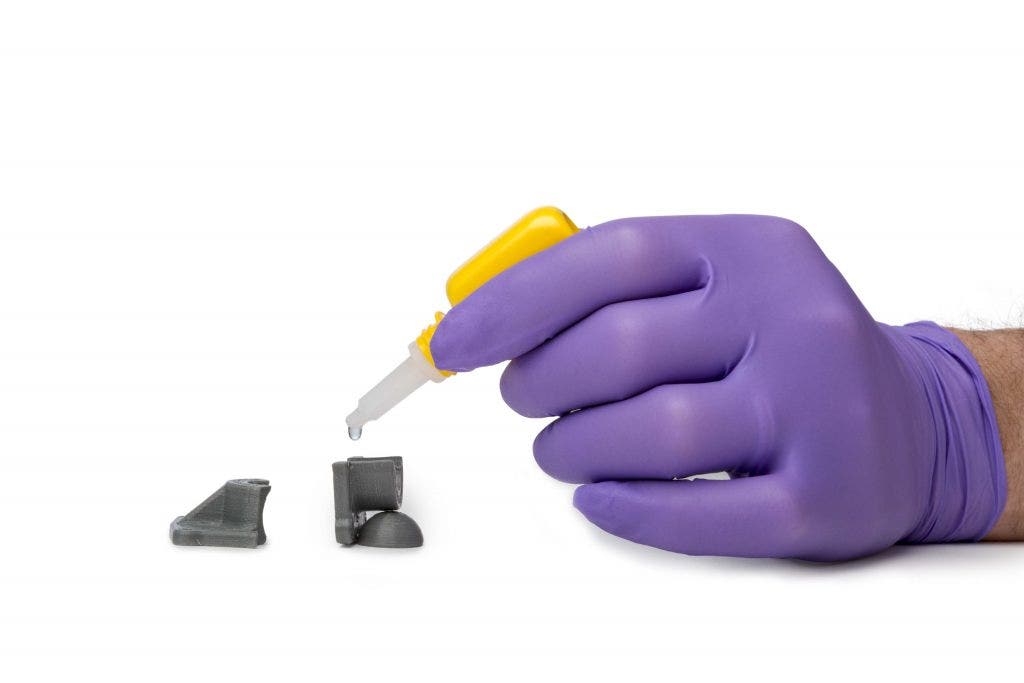

Now, once a print comes of the printer and you want to be doing something truly functional with it you may need some kind of post-processing with it, also called secondary operations. Be it painting, drilling or glueing there are multiple ways to work with a printed object once it has been printed, but before you can use it. You can truly bring 3D printing into your life by making useful applications.

For instance, you need to drill into a part. This should be no problem with co-polyesters. We recommend drills specifically made for plastic. Steel drills are possible, but only when grounded.