Mifa: Or how 3D printing helps in production

May 17, 2018

There are many ways 3D printing can be used: prototyping, final products, gadgets, investment casting, art, etc. But companies, especially the ones where physical products are being made, are increasingly looking at 3D printing for something else: tools, fixtures and parts in production. Like Mifa does. Mifa is a nearby company specialized in aluminium profiles.

Mifa is a leading company in the extrusion of magnesium profiles and aluminium profiles. They produce fully-finished precision products with dimensional tolerances from ± 0.02 mm. This level of aluminium extrusion precision means unprecedented possibilities. It gives designers enormous freedom in design, without the restrictions of standard specifications. As a result of this it is possible to achieve the optimum product.

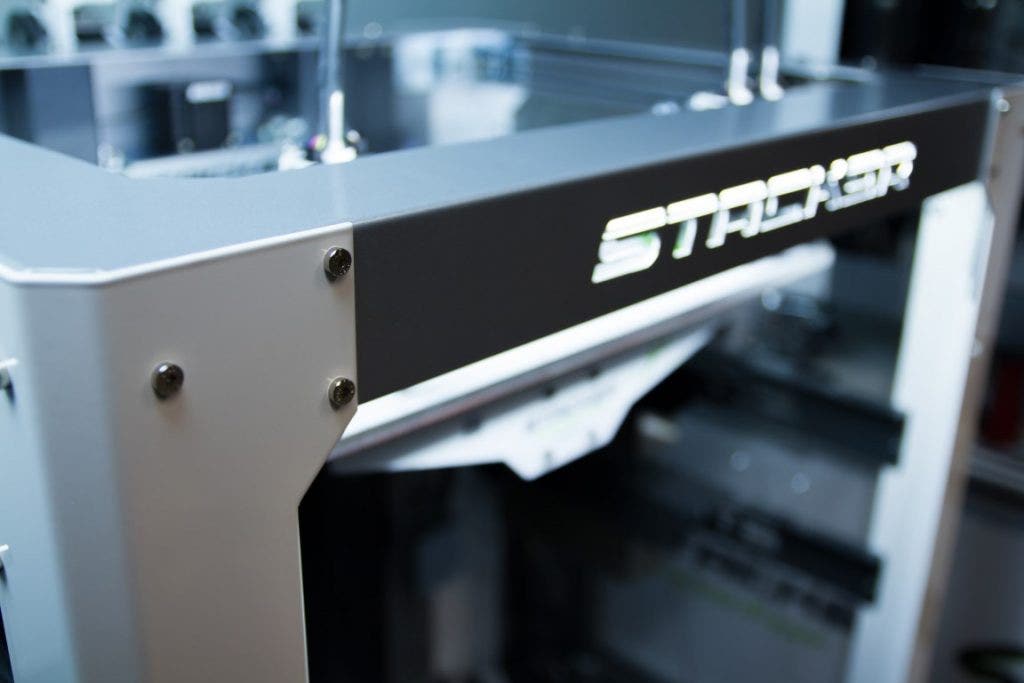

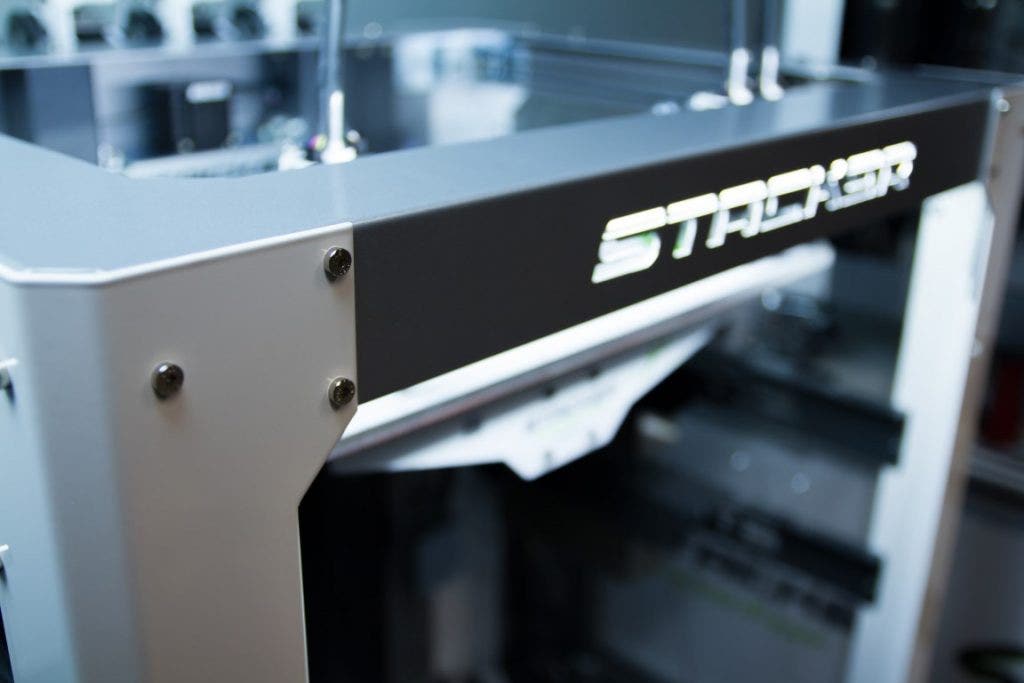

About a year ago Mifa made the decision to purchase a Stacker S4 printer. Because internally there was not enough capacity in house to have tooling made the conventional way, they started with their first Ultimaker at the end of 2015. We talked with Daan Broeksteeg, project engineer, why they use 3D printing and the Stacker in combination with colorFabb filaments in particular.

“The primary goal was to print clamping devices for our CNC machines. However, we found that 3D printing has many advantages and is being used in almost all departments of our company one way or another,” says Daan. “For instance, molds to bundle packages in or verification molds.” The Ultimaker printers were a great start for Mifa to get to learn to process of 3D printing and get people familiar with the process, but the need arose for a more industrial printer. With colorFabb as Stacker’s distributor in the vicinity the contacts were easily made.

Daan says: “Stacker has added value because of the tight tolerances that are very important in CNC milling. Because Stacker produces four parts at the same time, the dimensional deviation between the prints is minimal. This is definitely the main advantage of the Stacker.” As from the beginning Mifa uses colorFabb_XT for its parts. colorFabb_XT is made with Amphora AM1800 3D polymer is a low-odor, styrene-free choice that is uniquely suited for 3D printing applications. Daan explains why:

“We have done extensive research for the best material we should use. We found that colorFabb_XT has minimal moisture absorption (<1%) which is a benefit in a CNC environment with coolant nearby.”

It is clear that the Stacker 3D printer in combination with the right materials has advantages for Mifa’s CNC department. And it doesn’t stop there. Daan explains that as 3D printing is used in multiple departments, the printers are moving around a bit. It is the goal to have a dedicated print lab in the near future.

Mifa is another great example of how 3D printing brings added value to a company that needs reliability and quality delivered to its customers. The match of the Stacker printer with our range of functional co-polyesters, is a perfect all-in-one solution.

The Stacker S2 and S4 are industrial grade FFF 3D printers. Multiple print heads and a large build volume make them versatile printers. Small series production or large scale prototyping are no problem for the Stacker printers! This US based printer is very reliable and is a perfect match for any professional looking for serious 3D printing.

For Stacker the term “industrial grade” is not a hollow marketing term. It means their printers are designed for extra long service life, extremely low maintenance and that the printer will maintain its positional accuracy throughout its life cycle. This printer has been designed to be used in a professional environment, be it for large prototypes or small series production.

As many of you know, we are the distributor of Stacker 3D printers in Europe. We have been working with Stacker ever since their first prototype and now have several in our print lab. In the past 5 years we have seen 3D printing emerging from a hobby market to more professional uses. A lot of our users are using 3D printing to make a living or at least support their business in one way or another.

Testing 3d printed clamping parts at Mifa

We thank Daan Broeksteeg for his contribution to this blog.