allpha

- April 29, 2025

A Circular 3D Printing Revolution

Turning local Eggshells into Sustainable 3D Printing FilamentWe believe the future of 3D printing is sustainable, circular, and rooted in local solutions. That’s why we are proud to launch Print the Planet Green: a groundbreaking initiative that reimagines waste as opportunity. By transforming discarded eggshells into a high-performance, biobased PHA 3D printing filament, we are pushing the boundaries of circular economy practices and reshaping the materials landscape of additive manufacturing.

Our mission is clear: to empower local communities, minimize environmental impact and create value through smart, regenerative design.

Through strong collaborations with visionary partners and support from regional and European initiatives, we are driving a shift towards a cleaner, greener future — one locally sourced filament at a time.

Local 3D printing materials

We research and develop 3D printing filament by repurposing local natural materials,

- Februari 20, 2025

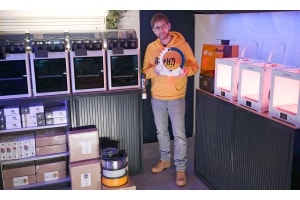

COLORFABB'S BIODEGRADABLE AND SUSTAINABLE FILAMENTS

CIRCULAR MATERIALS DESIGNED BY NATURE

Polyhydroxyalkanoate (PHAs) polymer filament is a material made and eaten by micro organisms (bacteria). PHA is often called the sleeping giant of polymers. It provides a unique opportunity as a solution for reducing greenhouse gases, environmental plastics pollution, and establishing a circular economy.

Our filament allPHA is made out of natural materials as a replacement for traditional petrochemical plastics. One could label this material as bioplastics and biopolymers. They are based on various PHA building blocks.

allPHA is 100% biodegradable and since it is a fully natural material, produced through bacterial fermentation, it contains no microplastics.

With sustainability and circularity at the top of our priorities, we can say we have created a material for additive manufacturing which not only delivers a great material to print with, but is also good for the environment.

PH... WHAT?!