colorFabb_HT – made with Eastman Tritan™

June 10th, 2021 (updated)

COLORFABB_HT: TRITAN TECHNOLOGY

colorFabb_HT is made with Eastman Amphora™ HT5300 and is a low-odor and styrene-free material uniquely suited for advanced 3D printing users, particularly those who need their models to exhibit excellent durability, toughness and high temperature resistance with a Tg of over 100⁰C. Amphora is Eastman’s brand of co-polyesters dedicated for 3D printing. Our nGen, colorFabb_XT and nGen_FLEX are also made with Amphora materials.

colorFabb_HT is enabled by Eastman Tritan™ copolyester technology. Tritan is Eastman’s flagship product and has been succesfully added to the 3D printing portfolio with colorFabb_HT. Learn more about Tritan on Eastman’s dedicated website.

Did you know that colorFabb_HT is a great alternative to materials like PCTG and ABS?

COPOLYESTERS EXPLAINED

The way we see it, FDM 3D printing filaments will be all about functionality in the future. How you are going to use your prints in the real world will define what material you choose. We have found a lot of characteristics in Eastman’s range of Amphora co-polyesters that offer functionality, durability and efficiency. Added benefits compared to ABS are the low-odor while printing and that Amphora based filaments are styrene free.

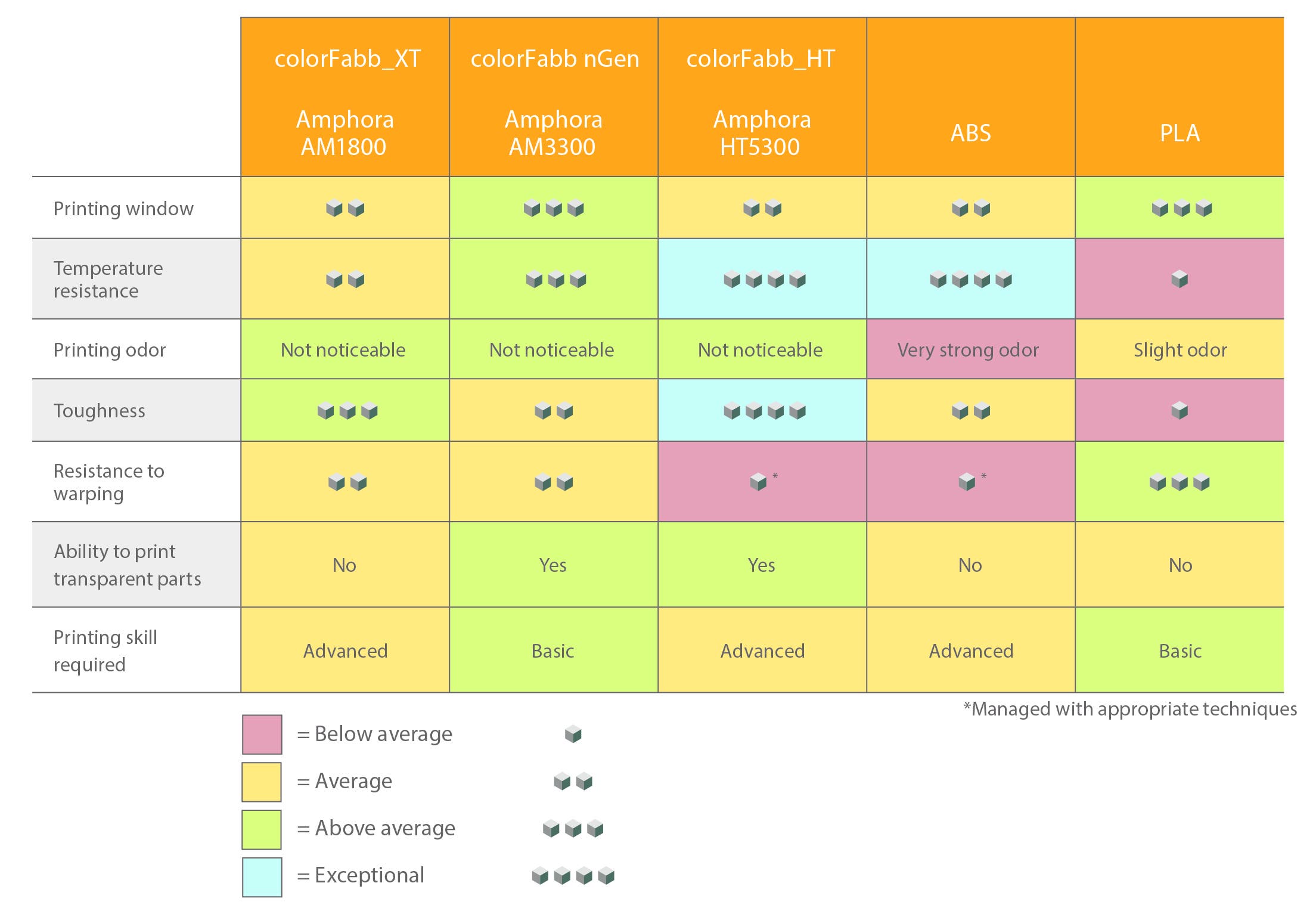

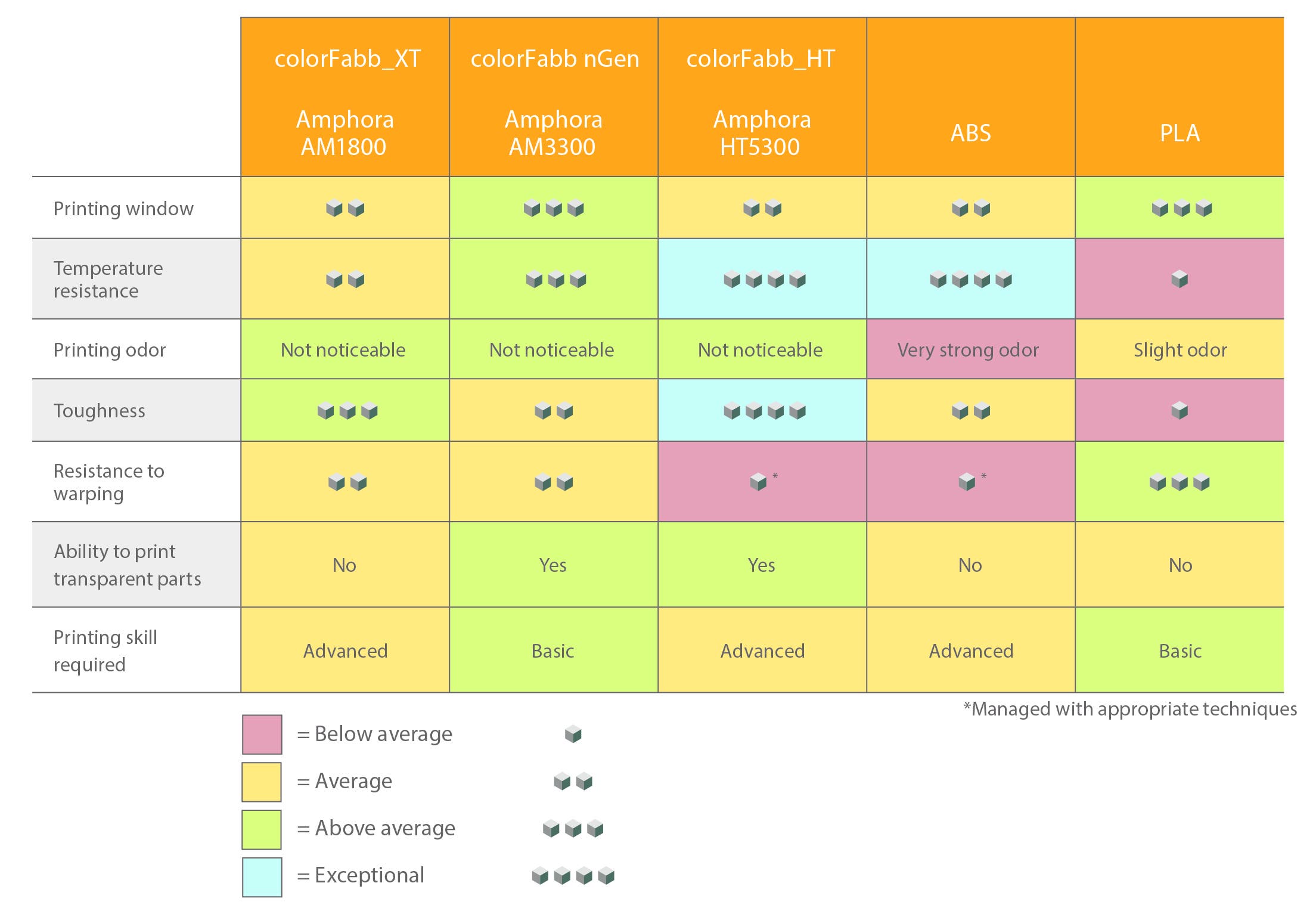

Compared to PLA, Amphora features a much better heat resistance, starting at 75C for colorFabb XT, 85C for colorFabb nGen and 100C for colorFabb HT. Below is a chart how our range of co-polyesters compare to other materials like PLA and ABS:

colorFabb_HT is very well suited for advanced 3D printing users, particular those who need their creations to exhibit excellent durability, toughness and temperature resistance.

CLEAR PRINTS

One of the unique features of colorFabb_HT is the ability to print near transparent parts. Due to the high flow characteristics it is now possible to print parts that are almost see-through. Due to the process of 3D printing, there is always a limit to how clear your print will become. With most materials the small gaps in between the 3D printed lines never really gets filled, resulting in a milky look when printing with transparent filaments. colorFabb_HT manages to fully close these gaps, resulting in a fully solid and transparent part.

Learn more by visiting our blog:

3D printing transparent parts. Possible with colorFabb_HT

"Impressive strength and printability... if you need a strong filament for prototypes or industrial use, HT is a great choice." -- user review

Availability

colorFabb_HT has been a hit since its launch in 2015 with professional users. We currently offer various colors, all of them shipping from stock as spools containing 700 grams and in some cases as 2kg spools. Check our website and stock levels for availability.

High tech clamps, printed with colorFabb_HT on the Leapfrog Bolt by Peter de Corte

Vertical windmill by Michael Broderick.

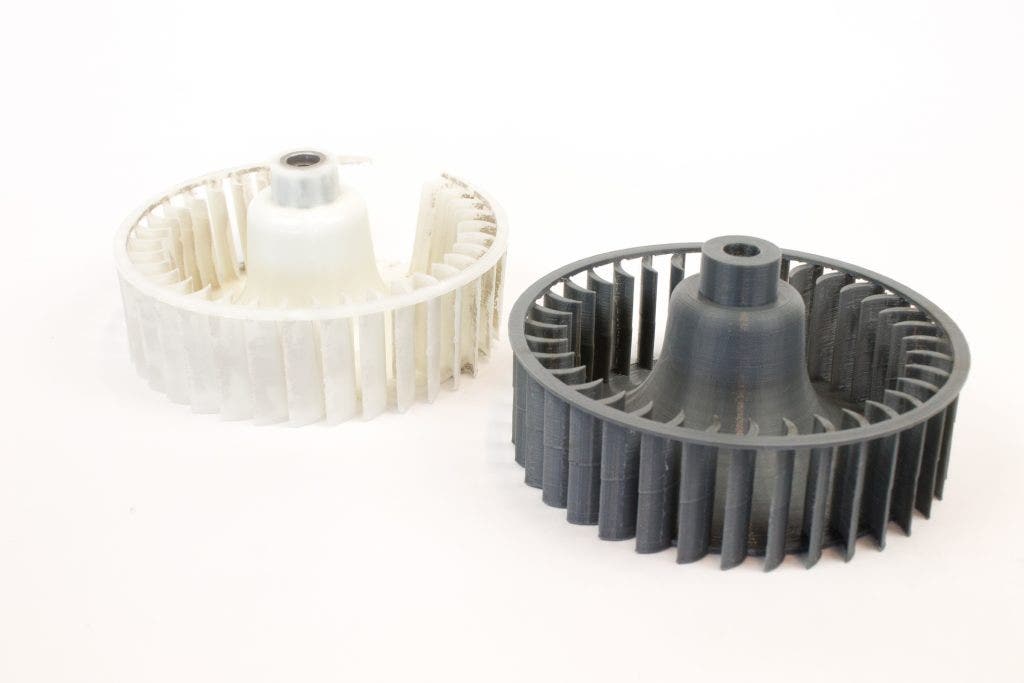

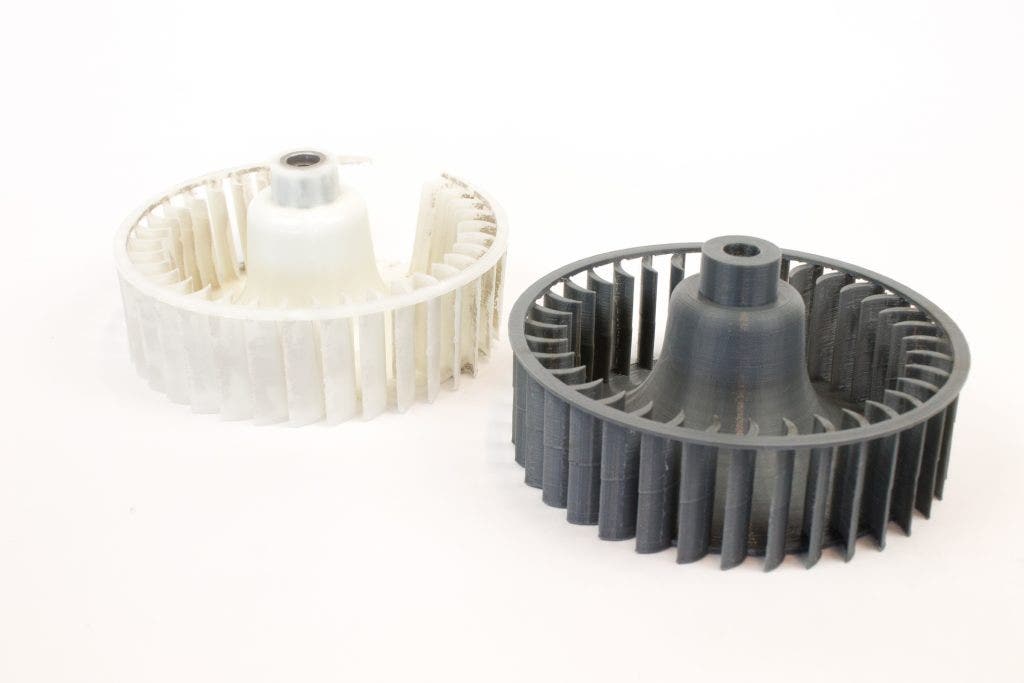

Old and broken laundry dryer part left, new printed one on the right.

Brushless motor by MakeSEA, colorFabb_HT print in combination with steelFill.

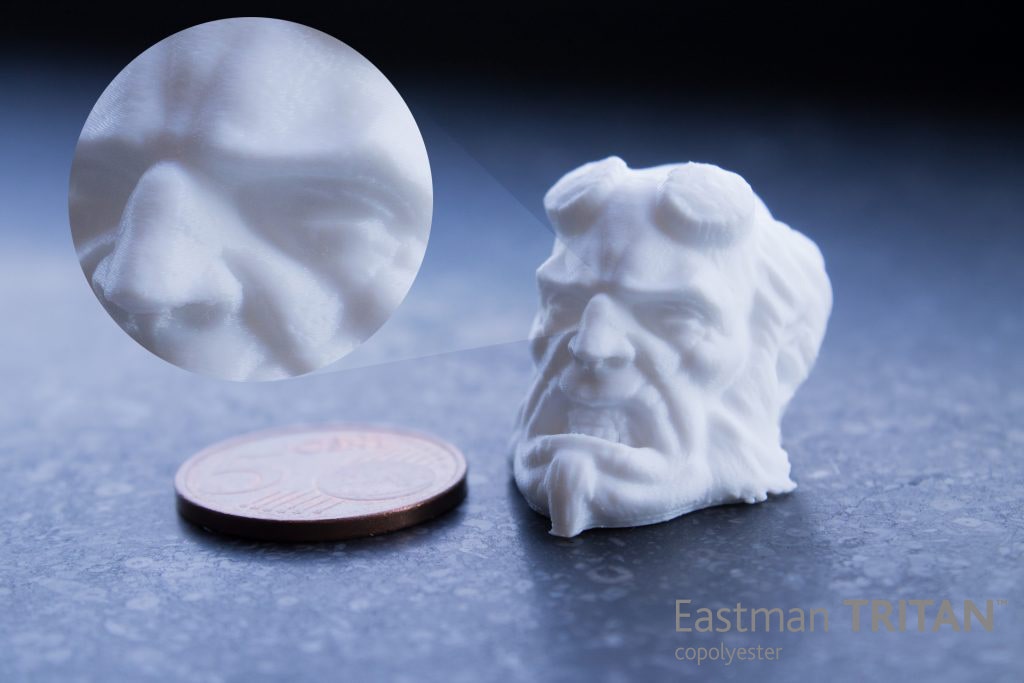

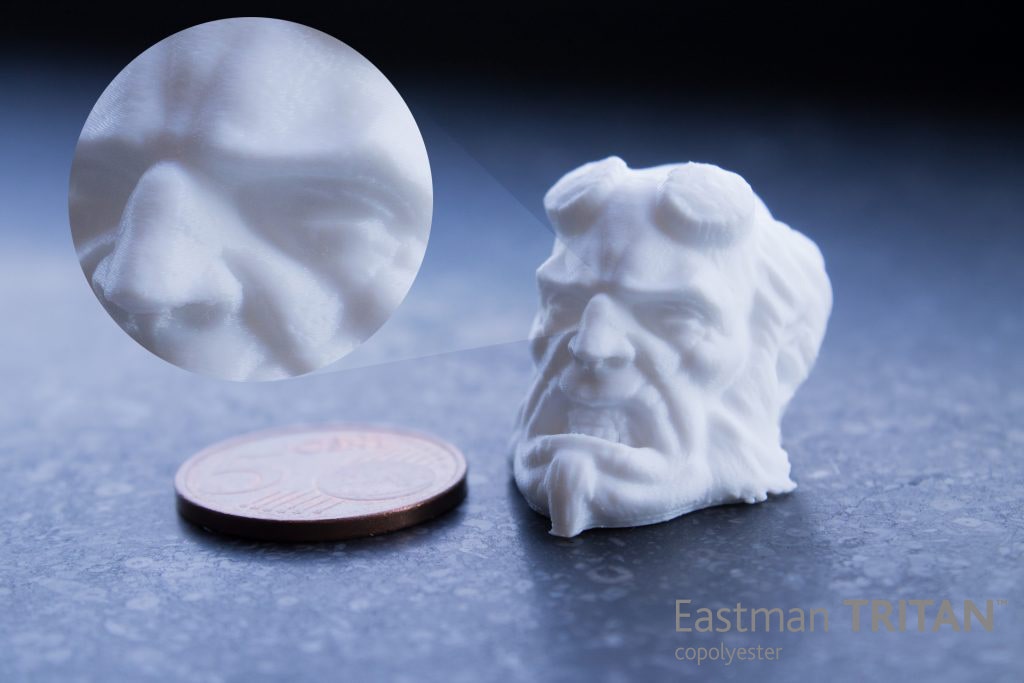

Even at the smallest prints colorFabb_HT performs outstanding. Design by Geoff W/Hex3D