How to Use ColorFabb Filaments on a Bambu Lab Printer: Optimizing Settings for High-Quality Prints

Bambu Lab printers are known for their advanced features, precision, and multi-material capabilities. Combining these capabilities with ColorFabb’s high-quality filaments opens up endless possibilities for creating durable, detailed, and aesthetically impressive 3D prints. However, to achieve the best results, it’s essential to optimize your settings for each filament type, as different materials have unique properties that influence how they behave during printing.

In this guide, we’ll take you through how to successfully use ColorFabb filaments on Bambu Lab printers. We’ll cover optimal settings, material compatibility, and tips for using the Automatic Material System (AMS) for multi-material printing. Whether you’re working with PLA, PETG, nGen, or more specialized materials like LW-PLA or carbon fiber-infused filaments, this guide will help you unlock the full potential of both ColorFabb materials and your Bambu Lab printer.

Why Choose ColorFabb Filaments for Your Bambu Lab Printer?

ColorFabb offers a broad range of filaments that stand out for their quality, consistency, and specialized properties. Each material in the ColorFabb lineup is designed to meet specific needs, whether it’s high strength, flexibility, temperature resistance, or unique aesthetics. Bambu Lab printers, with their precise extrusion systems, heated beds, and multi-material capabilities, can fully utilize the unique properties of ColorFabb filaments.

Advantages of Using ColorFabb Filaments with Bambu Lab Printers

- Broad Material Compatibility: ColorFabb offers filaments ranging from easy-to-use PLA to more complex materials like carbon fiber composites, all of which are compatible with Bambu Lab’s advanced hardware.

- Optimized Multi-Material Printing: The Bambu Lab Automatic Material System (AMS) makes it easy to switch between different ColorFabb filaments in a single print job.

- High Print Quality: With optimized settings, you can achieve consistent, high-quality results that showcase the characteristics of each ColorFabb material.

- Durability and Special Properties: ColorFabb’s specialty filaments, such as LW-PLA and PA-CF Low Warp, allow you to create parts with enhanced durability, weight reduction, or high-temperature resistance.

Setting Up Your Bambu Lab Printer for ColorFabb Filaments

Basic Setup and Calibration

Before diving into specific settings for different filaments, it’s important to ensure that your Bambu Lab printer is properly calibrated. Start with the following steps:

- Bed Leveling: Ensure your print bed is leveled for optimal first-layer adhesion. Bambu Lab printers typically have automatic bed leveling, but it’s good to double-check for consistency.

- Extruder Calibration: Verify that your extruder is calibrated correctly to avoid under-extrusion or over-extrusion, which can affect print quality, especially with materials like carbon fiber composites or flexible filaments.

- AMS (Automatic Material System): If you’re using the AMS, ensure each filament slot is loaded properly and that filament paths are clear to avoid jams during multi-material printing.

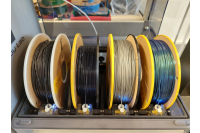

Loading ColorFabb Filaments into the AMS

The Bambu Lab AMS (Automatic Material System) is a powerful tool for managing multiple filaments in a single print job. Here’s how to load and use ColorFabb filaments with AMS:

- Load Each Spool Carefully: Insert each ColorFabb filament spool into a separate slot in the AMS, ensuring it is compatible with AMS guidelines (standard spool size and filament diameter of 1.75 mm).

- Label Filaments: Use the AMS software interface to label each filament according to its type. This helps the printer automatically adjust temperature and extrusion settings based on the material.

- Moisture Management: Store filaments in a dry, controlled environment before use. Certain filaments, like nylon and TPU, are hygroscopic and can absorb moisture from the air, which can impact print quality.

Optimized Settings for ColorFabb Filaments on Bambu Lab Printers

Each ColorFabb filament type has its own unique print requirements. Below are optimized settings for popular ColorFabb filaments when printing on a Bambu Lab printer.

1. PLA and PLA/PHA

ColorFabb’s PLA and PLA/PHA are easy-to-use filaments that work well with Bambu Lab printers. PLA/PHA, in particular, has enhanced durability compared to standard PLA.

- Extruder Temperature: 195°C - 220°C

- Bed Temperature: 50°C - 60°C

- Print Speed: 50 - 80 mm/s

- Cooling: 100% fan speed for optimal detail

- AMS Tips: PLA/PHA works well in the AMS with minimal adjustments. However, be mindful of humidity, as PLA can absorb moisture over time.

2. PETG

ColorFabb PETG is strong, durable, and has good resistance to impact and temperature. It’s ideal for functional parts that require more durability than PLA.

- Extruder Temperature: 230°C - 250°C

- Bed Temperature: 70°C - 80°C

- Print Speed: 40 - 60 mm/s

- Cooling: 50% - 70% to prevent warping

- AMS Tips: PETG can work well with AMS, but be cautious about stringing. Using a spool cover or drying box is recommended to keep PETG dry.

3. nGen

nGen is a versatile co-polyester that combines the ease of PLA with the durability of ABS. It has good chemical resistance and layer adhesion.

- Extruder Temperature: 220°C - 240°C

- Bed Temperature: 75°C

- Print Speed: 40 - 60 mm/s

- Cooling: 50% for consistent layer adhesion

- AMS Tips: nGen is compatible with AMS, but keep retraction settings optimized to avoid stringing.

4. LW-PLA

LW-PLA (Lightweight PLA) is a specialty filament that foams during extrusion, allowing you to control the density and weight of your prints. This makes it perfect for drones, RC planes, and other lightweight applications.

- Extruder Temperature: 210°C - 250°C (higher temperature for increased foaming)

- Bed Temperature: 40°C - 60°C

- Print Speed: 35 - 55 mm/s

- Cooling: 100% for detailed parts

- AMS Tips: Due to the foaming nature of LW-PLA, it may need manual monitoring in AMS. Experiment with extrusion settings for optimal foaming.

5. PA-CF Low Warp (Nylon with Carbon Fiber)

PA-CF Low Warp is a nylon filament reinforced with carbon fiber, providing strength, heat resistance, and minimal warping. This filament is ideal for high-strength functional parts.

- Extruder Temperature: 260°C - 280°C

- Bed Temperature: 100°C

- Print Speed: 30 - 50 mm/s

- Cooling: Off or minimal cooling

- AMS Tips: PA-CF Low Warp is hygroscopic, meaning it absorbs moisture. Store in a dry box and avoid using AMS unless the filament path is dry to prevent jams.

6. TPU (Flexible Filament)

ColorFabb TPU is a flexible material with good durability and resistance to wear, making it suitable for parts that require flexibility, such as gaskets, grips, and wearable items.

- Extruder Temperature: 210°C - 230°C

- Bed Temperature: 50°C

- Print Speed: 20 - 30 mm/s (slower speeds improve print quality)

- Cooling: 50% for balanced adhesion

- AMS Tips: TPU can be challenging in the AMS due to its flexibility. A direct drive extruder may perform better, so consider bypassing AMS for TPU.

Tips for Printing ColorFabb Filaments on Bambu Lab Printers

- Dry Your Filament: Certain ColorFabb filaments, like PA-CF Low Warp and TPU, are hygroscopic and should be kept dry. Use a filament dryer or store them in an airtight container with desiccant before printing.

- Optimize Retraction Settings: Retraction settings are crucial for achieving clean prints, especially with materials like PETG and TPU, which can be prone to stringing.

- Use Enclosures for High-Temperature Materials: When printing high-temperature filaments like PA-CF Low Warp, use an enclosure if possible to maintain a stable temperature and prevent warping.

- Experiment with AMS for Multi-Material Prints: Bambu Lab’s AMS allows you to print with multiple materials in a single job. Experiment with combinations like PLA for structure and TPU for flexibility to create functional, multi-material parts.

- Test Print Settings: Each ColorFabb filament has unique characteristics, so don’t hesitate to test different settings to find the optimal balance between quality and speed.

Troubleshooting Common Issues

Stringing or Oozing

Solution: Adjust retraction settings and lower the extruder temperature. Materials like PETG and TPU are prone to stringing if retraction is too low or the temperature is too high.

Warping

Solution: Use a heated bed, and for higher-temperature materials like PA-CF, consider enclosing your printer. Warping is often minimized with the right bed adhesion and stable ambient temperature.

Inconsistent Extrusion

Solution: Ensure the filament path is smooth and free from obstructions, especially when using AMS. If you’re printing with a high-temperature material, make sure your extruder can maintain a stable temperature.

Conclusion

Using ColorFabb filaments on a Bambu Lab printer can unlock a new level of quality and versatility in your 3D printing projects. By optimizing settings based on each filament’s unique properties, you can achieve impressive results for a wide range of applications—from lightweight parts with LW-PLA to durable, weather-resistant components with PA-CF Low Warp. The Bambu Lab AMS further enhances the experience, allowing for seamless multi-material printing.

Experiment with these settings and tips, and you’ll soon see how ColorFabb’s high-quality materials and Bambu Lab’s advanced printing technology make an unbeatable combination for professional and hobbyist 3D printing.