pa-cf

- February 20, 2025

Is your classic car part off the market?

Is 3D printing your sollution?

There are already quite a few car brands, and not just the exclusive ones, that use 3D printing for the production of individual replacement parts. Each car brand keeps car parts available on the market for a certain period. It depends on the necessity of the part in the car as well as for which period – in general for at least 10 years. So, whether you’ve turned your car into a classic one or you bought your oldtime favorite, the availability of high-quality parts can be a challenge.

PART OR NOT TO (CAR) PART!

Another reason to keep reading and find more information on the subject you're intersted in.

HONESTLY?

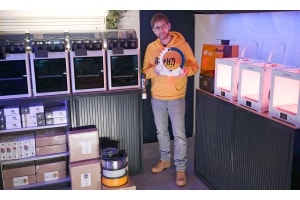

Of course our specialty is developing the best 3D print filaments in the world, not car parts. In addition to this, not all filaments are suitable for the job. In such cases, you’ll need to choose your preferred way of how you want to print. Here, we offer material for the FFF/FDM printing technique.

- December 19, 2024

The automotive world is experiencing a revolution, and at the forefront of this change is 3D printing. Whether you're restoring a vintage car, designing custom parts for performance upgrades, or creating prototypes for automotive projects, 3D printing has become an invaluable tool for both hobbyists and professionals. With ColorFabb’s high-quality filaments, crafting precise, durable, and customizable car parts is easier than ever.

From replacing rare components to building unique accessories, 3D printing offers a versatile, cost-effective way to bring your ideas to life. In this article, we’ll explore how you can use ColorFabb materials to 3D print car parts, delve into the practical applications, and highlight the advantages of integrating 3D printing into your automotive projects.

Why Use 3D Printing for Car Parts?

Traditional manufacturing methods for automotive parts often involve expensive tooling, long production cycles, and limited customization options. With 3D printing, however,

- November 01, 2024

How to Print with PA-CF Low Warp: The Ultimate Guide to 3D Printing Carbon Fiber Nylon

PA-CF Low Warp by ColorFabb is a game-changer in the world of 3D printing. This carbon fiber-reinforced nylon filament offers a unique balance of strength, durability, and dimensional stability, making it ideal for high-performance applications. Traditionally, printing with nylon can be challenging due to issues with warping, but ColorFabb’s PA-CF Low Warp has been specially formulated to minimize this problem. With the added strength of carbon fiber, this filament is well-suited for creating parts that need to withstand stress, heat, or demanding environments.

In this comprehensive guide, we'll explore how to print with PA-CF Low Warp, covering the optimal printer setup, recommended settings, and troubleshooting tips. Whether you’re a hobbyist or a professional, this guide will help you unlock the full potential of PA-CF Low Warp to produce exceptional, high-strength 3D prints.

What is PA-CF Low Warp?