How to 3D Print Your Own Garden Lamp: A Complete Guide to Functional, Durable Outdoor Lighting

Stuff breaks. It’s a simple fact of life. But, as the saying goes, life isn’t about avoiding every fall—it’s about how you get back up. The same is true for the objects around us: it’s not just about preventing things from breaking, but about how we can repair or replace them when they do. Recently, our 3D printing team was presented with a unique challenge: a broken garden lamp that had been a fixture in the garden for nearly two decades. How did it break? There are a few theories floating around—maybe it was just the wear and tear of 20 years outdoors, or maybe an errant football kick by the owner’s son sealed its fate. Either way, it was clear that a replacement was in order.

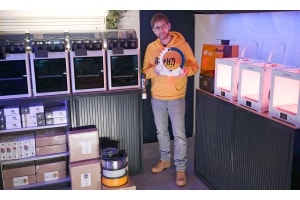

Our team set to work, creating a fresh 3D model based on the original lamp design (minus the cracks and layers of tape holding it together). Then, we did what we do best in our print lab: selected the ideal material and got to work crafting a beautiful and functional replacement.

For this print, we opted for PETG Economy Clear, a robust and transparent filament that’s perfectly suited for outdoor lighting fixtures. The transparency of the material allows light to pass through effectively, making it an ideal choice for a lamp cover. We chose the Ultimaker 2+ as our 3D printer for the job, using standard Ultimaker CPE settings with a 0.2mm layer height. The print quality turned out excellent, and no further adjustments were needed.

PETG Economy is an affordable, high-quality filament available in six popular colors and various spool sizes, making it an ideal choice for users looking to print large volumes of functional parts without breaking the bank. Below, we’ll dive into the process of designing, printing, and assembling a garden lamp, from choosing materials to setting up your printer and final assembly. Whether you’re tackling your own broken lamp or starting a new project, this guide will walk you through each step of 3D printing a unique and durable garden light.

Why 3D Print a Garden Lamp?

Creating a garden lamp with a 3D printer offers several advantages over buying a ready-made one. With 3D printing, you can customize every detail—from the design and size to the material and lighting options—ensuring that the lamp fits your outdoor space perfectly. Moreover, 3D printing allows you to replace or repair parts as needed, saving money and reducing waste. Printing a garden lamp also offers a rewarding DIY experience, combining creativity with engineering skills to produce a durable, weather-resistant outdoor fixture.

By choosing the right filament and design, you can ensure that your 3D-printed garden lamp withstands the elements, from UV rays and rain to temperature changes. Let’s dive deeper into the steps and considerations involved in creating your own 3D-printed garden lamp.

Step 1: Designing the 3D Printed Garden Lamp

The first stage in this project is to develop a design for your lamp. There are countless design possibilities, from modern geometric shapes to classic lantern styles. Here are some factors to consider when crafting your design:

1. Style and Shape

- Geometric Patterns: For a sleek, modern look, consider using geometric shapes like hexagons or triangles. These patterns also cast interesting shadows, adding an artistic touch to your garden.

- Organic Forms: If you prefer a softer, more natural look, organic shapes can complement the foliage in your garden, creating harmony between your lamp and its surroundings.

- Traditional Lanterns: Classic lantern designs bring an old-world charm to outdoor spaces. This style works particularly well with frosted or semi-transparent materials that create a warm, diffused glow.

2. Light Diffusion

- Consider how you want the light to be distributed. A transparent or translucent filament, like PETG Economy Clear, is ideal for allowing light to shine through while providing a softer, diffused glow that isn’t too harsh.

3. Size and Placement

- Decide how big you want the lamp to be. Small lamps are ideal for pathway lighting, while larger models can be statement pieces. Take into account your printer’s build volume when determining the lamp’s size, as larger designs may need to be printed in multiple parts.

4. Mounting Options

- Think about how you want to mount the lamp. Some people prefer freestanding lamps, while others may want them mounted on poles, hung from hooks, or even attached to a wall. Your mounting choice will affect the overall design and may require specific structural features.

Step 2: Selecting the Best Filament for Outdoor Use

Choosing the right filament is crucial for any 3D printing project, especially one that will be exposed to the elements. For this garden lamp, we selected PETG Economy Clear because of its strength, transparency, and weather resistance. Here are some key filament options for outdoor projects:

1. PETG Economy Clear

- PETG is an excellent choice for outdoor projects due to its high durability, flexibility, and UV resistance. The clear version allows light to pass through without being overly reflective, making it ideal for lamp covers. PETG is also resistant to moisture, making it suitable for wet environments.

2. ASA (Acrylonitrile Styrene Acrylate)

- ASA is similar to ABS but offers enhanced UV resistance, making it ideal for outdoor use. Its durability and weather resistance make it a suitable option for garden lamps that will be in direct sunlight.

3. PLA Blends

- PLA is typically not recommended for outdoor use because it degrades in sunlight and can warp in high temperatures. However, some PLA blends with added strength and UV resistance can work well for short-term outdoor projects.

4. Specialty Filaments (Translucent, Glow-in-the-Dark)

- If you want to get creative, translucent or glow-in-the-dark filaments can add an extra element of uniqueness to your lamp. These filaments might not be as durable as PETG or ASA but can be a fun choice for decorative projects.

Step 3: Optimizing 3D Printer Settings

Printing outdoor fixtures requires careful calibration of your printer settings to ensure a strong, weather-resistant finish. Here’s how we optimized the settings on our Ultimaker 2+ for the garden lamp project:

1. Layer Height

- We chose a layer height of 0.2mm, balancing print speed and surface smoothness. For decorative items, a lower layer height provides a finer finish, but for outdoor durability, 0.2mm is typically ideal.

2. Infill Density

- A higher infill density increases the print’s durability, which is important for items exposed to outdoor conditions. For this project, we went with an infill density of 20-30%, which provides sufficient strength without using excessive filament.

3. Wall Thickness

- We set a wall thickness of around 1.5mm to 2mm to ensure that the lamp cover would be sturdy and able to withstand outdoor conditions. Thicker walls also help protect against moisture and UV degradation.

4. Print Speed and Cooling

- We printed at a moderate speed to avoid print defects. Since PETG benefits from controlled cooling, we adjusted the fan settings to balance layer adhesion with surface quality.

Step 4: Post-Processing for Enhanced Weather Resistance

Once the print was complete, we took additional steps to prepare the lamp cover for outdoor use. Post-processing helps to seal the print, improving its resistance to moisture, sunlight, and temperature changes. Here are some steps to consider:

1. Sanding and Smoothing

- Light sanding can help smooth out rough surfaces and remove any imperfections from the printing process. Smoothing also prepares the surface for additional coatings, which can improve the lamp’s durability.

2. UV-Resistant Coating

- Applying a UV-resistant coating is essential for outdoor projects, especially for filaments like PLA or PETG. This coating helps prevent discoloration and degradation caused by prolonged sun exposure.

3. Waterproofing

- A waterproof varnish or epoxy coating can create an extra layer of protection against moisture, ensuring that your lamp lasts even through rain or humidity. Applying multiple coats and allowing each to dry thoroughly can maximize the effectiveness of this protection.

Step 5: Adding LED Lighting and Final Assembly

With the lamp cover printed and post-processed, the next step was to add the LED lighting. LEDs are energy-efficient and ideal for outdoor applications due to their low heat output and long lifespan. Here’s how we completed the assembly:

1. Choosing LED Bulbs

- We selected warm white LED bulbs to create a cozy, inviting atmosphere in the garden. LEDs come in various colors and intensities, so you can choose one that fits the mood you want to create.

2. Power Options

- Battery-powered LEDs are convenient and allow for easy placement without a power outlet. For sustainability, we recommend using solar-powered LEDs, which recharge during the day and light up at night.

3. Assembly

- After wiring the LED and placing it inside the lamp cover, we ensured it was secure and stable. The lamp cover was designed with a cavity for the LED, allowing the light to diffuse evenly without being exposed to the elements.

Why PETG Economy is Ideal for Large-Volume 3D Printing Projects

PETG Economy, offered by ColorFabb, has become a popular choice for functional, large-volume 3D printing projects. Here are five reasons why PETG Economy stands out:

- Durability: PETG is tough and resistant to impact, making it suitable for both indoor and outdoor projects.

- Transparency: The clear version allows light to pass through effectively, which is essential for lighting fixtures.

- Weather Resistance: PETG performs well under various environmental conditions, handling moisture and UV exposure better than standard PLA.

- Affordable: PETG Economy provides high quality at an affordable price, ideal for users needing large spools for big projects.

- Compatibility: It works well with many popular 3D printers and does not require extensive adjustments to print settings.

Creative Design Ideas for 3D Printed Garden Lamps

Here are a few ideas to inspire your garden lamp design:

- Pathway Lights: Create a set of small lamps to line your garden path, each designed with a different pattern or color for a charming, whimsical effect.

- Japanese Lanterns: Inspired by traditional Japanese designs, these lanterns have frosted panels and intricate detailing, adding a touch of elegance to any garden.

- Geometric Spheres: Use geometric patterns like hexagons or stars to create unique lamps that cast beautiful shadows.

- Nature-Inspired Designs: Incorporate elements like leaves or flowers into your lamp design, blending the lamp with your garden’s natural setting.

Troubleshooting Common Issues with 3D Printed Outdoor Lamps

Even with careful planning, 3D printing outdoor items can pose challenges. Here are solutions to some common issues:

- Warping: Increase the bed temperature or use an enclosure for materials like PETG and ASA.

- Poor Adhesion: Try raising the extrusion temperature or lowering the print speed to improve layer bonding.

- Moisture Issues: Store filament in a dry environment, as materials like PETG can absorb moisture.