RC Wing 3D Printer: Revolutionizing Lightweight Model Aircraft with ColorFabb LW-PLA

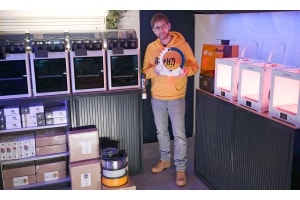

At RC Wing 3D Printer (https://rcwing3dprinter.com), our passion lies in designing and crafting innovative, lightweight, and efficient model aircraft that elevate the experience of remote-controlled flying. Leveraging cutting-edge 3D printing technology and the unique properties of ColorFabb LW-PLA, we aim to create models that combine exceptional flight performance with simplicity in assembly and construction. Our designs are built with precision, practicality, and durability in mind, ensuring that even enthusiasts with smaller 3D printers can create high-performance planes.

This article dives into the meticulous development process of our aircraft models, the advantages of using ColorFabb LW-PLA, and the specifics of our flagship design, the Type M1 RC Wing. You’ll also find step-by-step resources and detailed specifications to help you build and fly your own model with confidence.

Why ColorFabb LW-PLA is the Game-Changer in RC Model Design

The development of our RC models centers on achieving lightweight, durable, and efficient designs, and ColorFabb LW-PLA (Lightweight PLA) plays a pivotal role in helping us meet these goals. This revolutionary filament is specifically engineered for lightweight applications, making it the perfect material for creating RC aircraft that excel in both flight dynamics and structural integrity.

Key features of ColorFabb LW-PLA:

- Weight Reduction: During the printing process, LW-PLA expands by up to 3 times its original volume when heated, allowing you to use less filament to achieve lighter parts. This is critical in model aircraft, where every gram matters.

- Strength and Stability: Despite its lightweight properties, LW-PLA maintains enough strength and rigidity to withstand the demands of high-speed and acrobatic flight.

- Customizable Density: By adjusting print settings (such as temperature and extrusion multiplier), you can control the expansion of LW-PLA, optimizing weight-to-strength ratios for specific components.

- Smooth Surface Finish: LW-PLA offers a clean and professional finish, which is important for aerodynamic performance and aesthetics.

For the Type M1 RC Wing, these properties translate into a final print weight of just 520 grams, making it one of the most efficient and lightweight RC models available in its class.

Design Philosophy: Simplifying Construction Without Compromising Performance

At RC Wing 3D Printer, we believe that building high-quality RC aircraft should be an accessible and enjoyable process. With that in mind, we focus on several key principles during the development of our models:

1. Low Print Volume Requirements

- Our designs are optimized to fit within the build volume of most consumer-grade 3D printers. For example, the Type M1 requires a print volume of just 220 x 220 x 250 mm, ensuring compatibility with printers like the Ender 3, Prusa i3, and many others.

2. Reducing the Number of Parts

- By consolidating components into larger, multi-functional pieces, we minimize the total number of printed parts. This simplifies assembly and reduces the risk of structural weaknesses caused by excess joints or seams. The Type M1 requires only 25 printed parts, a remarkably low number for an RC aircraft of its size and performance capabilities.

3. Limiting Non-Printed Accessories

- To ensure that the aircraft is easy to build and affordable, we limit the use of non-printed parts to only what is absolutely necessary. For the Type M1, the only external accessories required are:

- Screws for engine mounting

- A carbon tube for reinforcing the fuselage and wings

4. Simplified Assembly with Universal Adhesive

- All printed parts are designed to be assembled using UHU Alplast, a transparent and powerful universal adhesive suitable for plastics. This eliminates the need for complex tools or specialized equipment, streamlining the construction process for users of all skill levels.

The RC Wing Type M1: Specifications and Performance Highlights

The Type M1 RC Wing is a lightweight, high-performance aircraft designed to excel in both acrobatic maneuvers and slow, stable flights. Here’s an overview of the key details and performance highlights of this incredible model:

1. Print Specifications

- 3D Printer Build Volume: 220 x 220 x 250 mm (suitable for small and medium-sized 3D printers)

- Printed Parts: 25 pieces

- Non-Printed Accessories:

- Screws for engine mounting

- Carbon tube for fuselage and wing reinforcement

- Total Weight: 520 grams (when printed with ColorFabb LW-PLA)

- Adhesive for Assembly: UHU Alplast universal adhesive

2. Assembly Resources

- Print Profile: Download the optimized LW-PLA print profile in PDF format for precise settings tailored to the Type M1.

- Fuselage Assembly Tutorial: Follow the step-by-step guide here: Watch Fuselage Assembly

- Wing Assembly Tutorial: Learn how to assemble the wings here: Watch Wing Assembly

3. Maiden Flight: Outstanding Performance

The Type M1 has undergone rigorous testing to ensure it meets our high standards for flight performance. During its maiden flight, the Type M1 exceeded all expectations:

- Acrobatic Durability: The lightweight yet robust structure makes it virtually indestructible during acrobatic maneuvers.

- Smooth Flight Characteristics: The Type M1 delivers a smooth and responsive flying experience, making it suitable for both beginners and experienced pilots.

- Stable Slow Flight: The design and material ensure stability even at slower speeds, allowing for precise control during landing and low-speed maneuvers.

Step-by-Step Instructions for Printing and Assembling the Type M1

Step 1: Printing with ColorFabb LW-PLA

- Load LW-PLA Filament: Ensure your printer is equipped with ColorFabb LW-PLA. Adjust your settings based on the provided Print Profile (PDF) to optimize the expansion properties of the filament.

- Printer Settings:

- Layer Height: 0.2mm for balanced strength and surface quality.

- Print Temperature: Adjust within the recommended range (200–230°C) to control the filament expansion.

- Infill Density: Use 20-40% infill for structural components, while wings and non-load-bearing parts can utilize lower infill to save weight.

- Print Volume: Ensure your printer can accommodate the required volume of 220 x 220 x 250 mm. Most consumer-grade printers will suffice.

Step 2: Assembling the Fuselage

- Watch the full video tutorial for fuselage assembly: Fuselage Assembly Guide.

- Bond the printed parts using UHU Alplast adhesive, ensuring precise alignment for structural integrity.

Step 3: Assembling the Wings

- Follow the detailed wing assembly guide here: Wing Assembly Tutorial.

- Reinforce the wings using the carbon tube, ensuring optimal strength without adding excessive weight.

Step 4: Final Assembly and Setup

- Mount the engine using screws.

- Perform final checks to ensure all parts are securely attached and aligned.

Why Choose the Type M1 RC Wing?

The Type M1 RC Wing is more than just a model aircraft—it’s a meticulously engineered fusion of design innovation, cutting-edge materials, and 3D printing technology. Whether you’re a seasoned RC enthusiast or a hobbyist looking to explore the possibilities of 3D printing, the Type M1 offers several compelling advantages:

- Lightweight and Durable: At just 520 grams, the Type M1 achieves an ideal weight-to-strength ratio for optimal flight performance.

- Easy to Build: With only 25 printed parts and minimal non-printed accessories, assembly is straightforward and beginner-friendly.

- Affordable and Accessible: Designed to work with standard 3D printers and cost-effective materials, the Type M1 is a budget-friendly option for high-performance RC models.

- Proven Flight Performance: From acrobatic stunts to slow, controlled landings, the Type M1 delivers exceptional stability and maneuverability.